Industrial Metaverse: How Virtual Spaces Are Transforming Manufacturing in Europe

The industrial metaverse is redefining how Europe builds, operates, and maintains its manufacturing sector. Driven by advancements in augmented reality (AR), virtual reality (VR), artificial intelligence (AI), and digital twins, this evolving ecosystem offers new ways to design factories, train workers, and optimise production processes. In 2025, European industries are no longer asking whether to invest in these technologies — they are accelerating integration to remain competitive in an increasingly digitised economy.

Integration of Digital Twins and Virtual Production Lines

Across European manufacturing hubs, digital twins are being deployed to mirror entire production environments in real time. These virtual replicas allow engineers to simulate workflows, test process improvements, and detect potential issues before implementing changes in physical settings. In Germany, Siemens has enhanced its smart factory operations by synchronising sensor data with 3D environments, enabling predictive maintenance and design iteration at unprecedented speeds.

Italy’s automotive sector is using virtual production lines to train workers and refine complex assembly processes. Workers don VR headsets to familiarise themselves with assembly stages, reducing the risk of human error and improving onboarding times. This blend of simulation and real-world interaction not only cuts costs but also contributes to safer working environments.

Additionally, French aerospace companies have begun integrating multi-user digital spaces for collaborative design. Engineers from various locations enter shared virtual environments to discuss component configurations in real time, thus minimising the need for costly travel and streamlining approval cycles.

Real-Time Data and Adaptive Manufacturing

The metaverse’s backbone is its capacity to ingest and utilise massive streams of real-time data. European manufacturers are merging IoT devices with metaverse platforms to monitor temperature, pressure, and vibration across machines. This constant stream of data allows AI systems to recommend dynamic adjustments, ensuring machinery always operates at peak efficiency.

In Denmark, smart food processing plants now respond to demand changes in real-time. Metaverse-based dashboards allow supervisors to visualise bottlenecks and reallocate resources within minutes. Such agility is reshaping how industries respond to both market and internal shifts.

The rise of adaptive manufacturing is especially critical for sustainability efforts. By simulating energy usage and emissions within virtual spaces, manufacturers can optimise resource consumption long before construction or deployment of actual systems. This aligns with the EU’s Green Deal goals for climate-neutral industry practices by 2050.

Reshaping Workforce Training and Operational Safety

One of the most immediate impacts of the industrial metaverse is seen in how training and safety protocols are delivered. In countries like Sweden and the Netherlands, companies deploy immersive VR training programs that simulate hazardous scenarios in controlled digital environments. Employees learn how to react to chemical spills or equipment failures without actual risk, greatly reducing workplace incidents.

Beyond safety, the metaverse is closing the skills gap. European vocational schools now partner with manufacturing firms to deliver metaverse-based curricula. Trainees learn by virtually operating CNC machines or robotic arms, shortening the transition time from classroom to production floor.

Moreover, multilingual digital assistants within these environments offer real-time guidance. Workers from diverse backgrounds receive instructions in their native languages, increasing comprehension and reducing operational mistakes. This inclusive approach helps expand the qualified labour pool across European manufacturing.

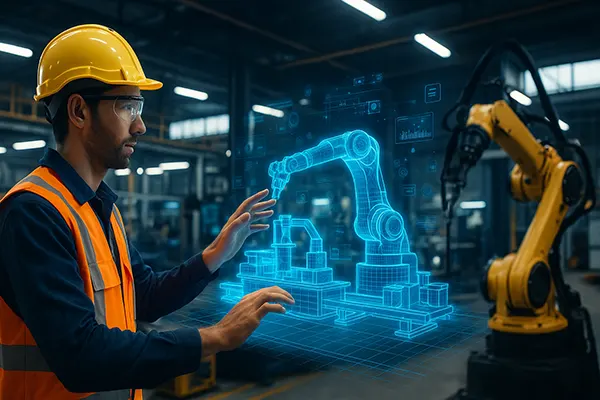

Human-Machine Collaboration in Virtual Ecosystems

In smart factories across Belgium and Austria, collaborative robots (cobots) are now integrated with digital avatars in the metaverse. Technicians can remotely pilot cobots or simulate repair procedures from afar, reducing downtime during urgent maintenance tasks. These hybrids of human expertise and robotic precision are accelerating problem-solving across industries.

The ability to visualise how machines interact with humans is helping refine ergonomic design. Using VR models, factory layouts are continuously adapted to reduce physical strain and improve worker comfort. These insights are then embedded into the design of future production environments.

Crucially, this collaborative layer also supports mental health. Simulated wellness spaces and guided stress-reduction programs within virtual environments are becoming part of routine operations, reflecting a growing commitment to holistic workforce wellbeing.

Regulatory Standards and Strategic Adoption in the EU

As industrial metaverse applications grow, EU institutions are setting frameworks to ensure ethical and standardised usage. In February 2025, the European Commission introduced the “Metaverse for Industry” directive, outlining data protection, interoperability, and cybersecurity mandates. The policy ensures safe integration of virtual spaces into sensitive manufacturing sectors.

Public-private partnerships are key to scaling adoption. The European Factories of the Future Research Association (EFFRA) continues to fund large-scale pilots, enabling SMEs to explore metaverse tools without prohibitive initial investment. These initiatives prioritise digital equity across diverse manufacturing segments, from textiles in Portugal to precision optics in the Czech Republic.

Finally, intellectual property (IP) protection within the metaverse is evolving. With entire product designs shared in immersive environments, new IP protocols are being drafted to secure innovation. The EU Intellectual Property Office has already proposed digital watermarking tools to trace ownership of virtual assets and industrial blueprints.

Future Outlook: From Pilot to Production

2025 marks a tipping point in Europe’s journey toward full industrial metaverse maturity. What began as pilot programs in isolated facilities is now scaling into cross-border digital ecosystems. Factories are becoming increasingly “phygital” — blending physical assets with persistent virtual layers that allow perpetual optimisation and co-creation.

Ongoing research into haptics and neural interfaces may soon elevate the level of immersion, giving workers tactile feedback while operating in digital environments. As bandwidth improves and edge computing expands, latency in virtual operations will drop, further boosting metaverse adoption.

With a cohesive regulatory approach, robust funding models, and clear economic incentives, Europe is poised to become a global leader in industrial metaverse innovation. The continent’s unique blend of technical expertise, ethical frameworks, and manufacturing heritage sets the stage for a revolutionary industrial renaissance.